Tel: +86-0512-87810606

WhatsApp: +86-18012620885

Skype: +86-18012620885

WeChat: +86-18012620885

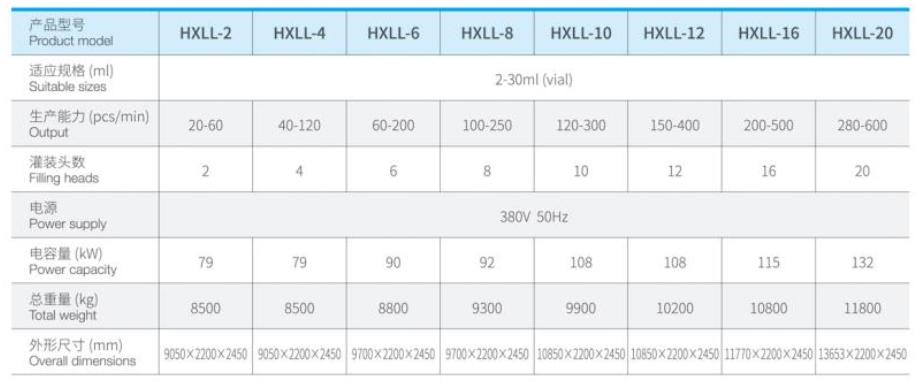

The linkage line consists of HQCLA series vertical ultrasonic washing machine, HSDH series hot air circulation sterilization tunnel, HSFG series filling and stoppering machine. The model can be used in combination or in a single machine. The linkage line can complete water spray filling, ultrasonic cleaning and flushing (internal and external), CA flushing (internal and external), preheating, drying and sterilizing to remove heat source, cooling, filling, sealing, capping, and other processes. This line can meet the size range from 2-30 ml vials of washing, drying and sterilizing to remove heat source, filling and sealing, requirements of the production process.

Vertical ultrasonic washing machine using ultrasonic rough washing circulating water, WFl and clean compressed air spray and clean the container alternately, Cleaning clarity and visible material detection effect is ideal; it is the most popular cleaning machine in the world today. The sterilization tunnel adopts the principle of hot air laminar flow and high temperature sterilization process to preheat, dry, sterilize, remove heat and sterilization process it is the most popular drying and sterilizing machine in the world.

The filling and stoppering machine adopts V shape block to transfer and reciprocating tracking filling which can ensure stable vials transfer, fulltime of filling and accurate filling volume. using progressive stoppering way to ensure high qualification rate, It is the most popular filling and sealing machine in the world.

The interlocking production line adopts PLC control and touch screen operation, which can be used for linkage control or stand-alone operation. The control runs stably and with high automation.